Design and control of agglomeration in spray dryers

Grant number

-

Project title

Efficient Design and control of Agglomeration in Spray Drying Maschines - EDECAD

Project leader

Prof. Dr.-Ing. habil. Martin Sommerfeld

Realized by

Dipl.-Ing. Stefan Blei

Keywords

Spray drying, agglomeration, sticky particles, collision model

Short description of the project

In the frame of the Euler/Lagrange approach an existing stochastic inter-particle collision model will be extended to the interaction of droplets and particles relevant for spray drying processes. The following situations will be considered:

- collision between droplets with consideration of droplet coalescence,

- collision between droplets and solid particles by accounting for agglomeration,

- collision and agglomeration of dried (sticky) particles.

The resulting collision models will be implemented in a subroutine and provided to the partners of the project-consortia for implementation into existing CFD-codes. The droplet collision model will be based on the data obtained from UMIST, Manchester.

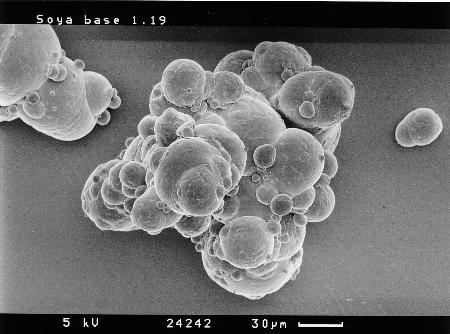

Photo: Milk powder agglomerat

Photo: Milk powder agglomerat

For the analysis of sticky particle collisions and collisions between particles and droplets detailed experiments will be performed at a laboratory-scale test facility. The interaction of particle-loaden jets will be studied by visualisation techniques and the particle streakline method. For this purpose a pulsed Na-Yag laser and high resolution CCD-camers combined with a macrolens will be used. The signal processing software will be further extended and refined to allow for a detailed analysis of the processes.