Droplet jet lyophilization - functional solid particles

Grant number

SO 204/36-3

Project title

Droplet jet - lyophilization for the synthesis of protein inhalants

Project leader

Prof. Dr.-Ing. habil. Martin Sommerfeld

Realized by

Stefan Wanning

Markus Jäger

Keywords

Therapeutic agent, inhalants, protein, lungs, pulmonary, lyophilisate, spray, freeze-drying, sublimation, lattice Boltzmann, Euler/Lagrange.

Short description of the project

The application of many biotechnological therapeutic agents through the lungs represents an approved alternative to intestinal medication since absorption is less hindered. However, pulmonary application requires specialized treatment of the active agents in terms of heat exposure and adjustment of adequate particle size distributions. In this project the experimental and theoretical fundamentals of a continuous synthesis of mono-disperse particulate lyophilisates by means of freeze-drying of a droplet jet are to be acquired. Thereto, a cooperation of a pharmaceutical-technological workgroup focused on micro-particulate systems and lyophilization (Prof. Dr. Lamprecht) and a process-engineering workgroup experienced in modeling, simulating and analyzing of multi-phase flows (Prof. Dr.-Ing. Sommerfeld) is established.

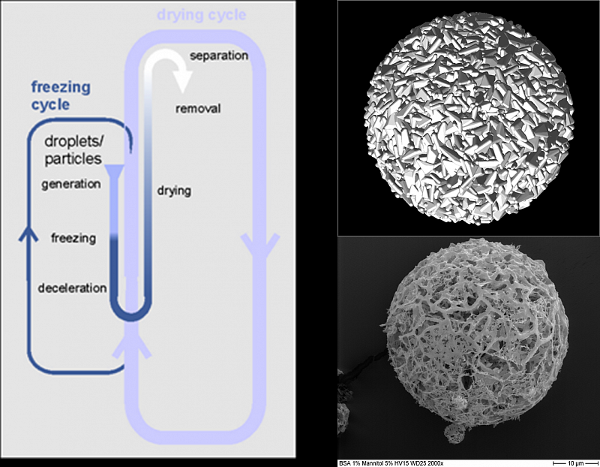

The technological process that is investigated involves the injection of an aqueous formulation into a downwards pointing jet of cooling gas by a dispenser resulting in a rapid crystallization of the liquid droplets. Subsequent to the freezing step the iced particles are collected in the lower section of the drying chamber by an upwards pointing jet of warm drying gas and hence are dehydrated by sublimation of the ice phase. Dry lyophilisates are removed in the top section of the drying chamber and separated from the working gas by a cyclone. It is expected that the particulate lyophilisates synthesized that way show a well-defined deposition behavior due to their uniform size, their adjustable porosity, their high specific surface and their ability to absorb water from the humidity-saturated atmosphere of the respiratory system.

Photo: Process of lyophilization , numerical and experimental lyophilizate

Photo: Process of lyophilization , numerical and experimental lyophilizate

The layout of the lyophilization process is supported by numerical simulations. The development of adequate models describing mass and heat transfer during the drying process is done within the scope of single particles using the lattice Boltzmann method. Highly resolved frozen particles are subjected to both a temperature filed and a flow field to determine the resulting mass transport from the ice to the steam phase. The established correlations describing the sublimation rate are implemented into the Euler/Lagrange approach which is used for simulating the drying process at the technical scale of the complete drying apparatus. Aim is the optimization of the geometric design of the drying chamber as well as of the flow and temperature conditions inside to realize a sufficient particle residence time and to improve the energy efficiency of the process.